Our passion first and foremost will always be t-shirts.

We specialise in producing retail quality screen printed T-shirts with a soft hand and lightweight finish. For over a decade we have obsessed with developing the ability to produce the most highly detailed, opaque, colour accurate and vibrant print finish on light or dark garments. Using a unique blend of High Solid Acrylic Waterbased Ink and Traditional Phthalate free Plastisol (which is very unique to the Flippin’ Sweet Print Co), using higher mesh counts and various techniques fine tuned over the years to ensure our finish printed product is light weight and has an impressive satin finish.

Printability

Screen print is still the most versatile and accurate way to reproduce your artwork ranging from simple single colour logos to full colour photographic designs. We have even been guilty of playing with special effects on ocassion, so if you’re looking for something with a little extra flare don’t hesitate to let us know!

Garment Choice

We have access to a huge range of garments in various brands and styles. T-shirts are our thing, with well over a decade of printing T-shirts and even longer working in the industry if there’s anything we know.. it’s a good quality T-shirt and we can help you source the perfect T-shirt for your project.

Volume

Your T-shirts are produced on a manual hand printed carousel or our state of the art automated screen printing machine. Meaning we can produce from as few as 20 T-shirts and upwards all the way up in to the 1000s decreasing in price the more you order.

We trust in the quality, availability, shape, fit, print finish and price provided by AScolour garments which is why we highly recommend AScolour as our print shop garment brand of choice. The garments below can all be decorated with up to a six colour screenprint and are also suitable for garment finishing such as re-labelling. Choose your product below for more infomation or get in touch to recieve a quote.

The garments above are just a handful of examples. We do have access to a huge range of garments from various brands in a range of styles such as these brands, so if you do not see what you need please don’t hesitate to get in touch for a quote and we’ll try our best to source the garment most suited to your specific needs.

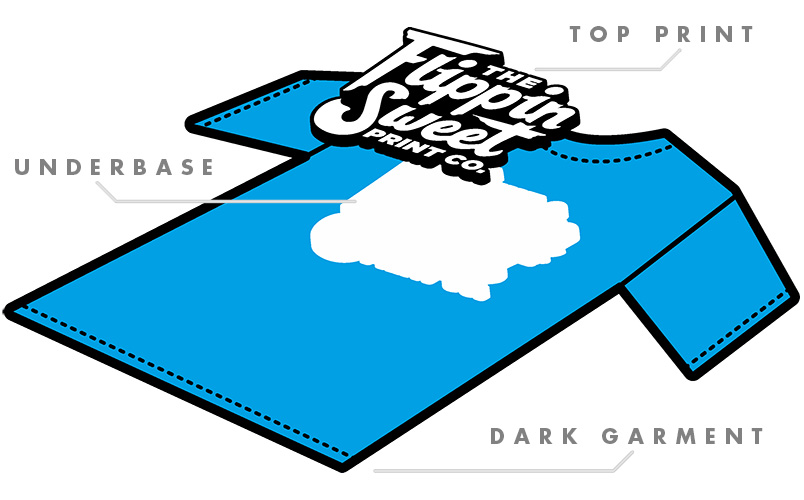

When screen printing on to dark or coloured garments certain designs may require the use of an underbase to achieve a vibrant opaque print finish (depending on the artwork and number of colours in the design). If your print design does require an underbase, we create an extra screen and the print is charged as one extra print colour. For example if your artwork features 3 colours such as red, green and blue on to a black t-shirt, this would be charged as a 4 colour screen print (White underbase, red, green and blue overprint).

Screen printing on to white garments does not require an underbase.

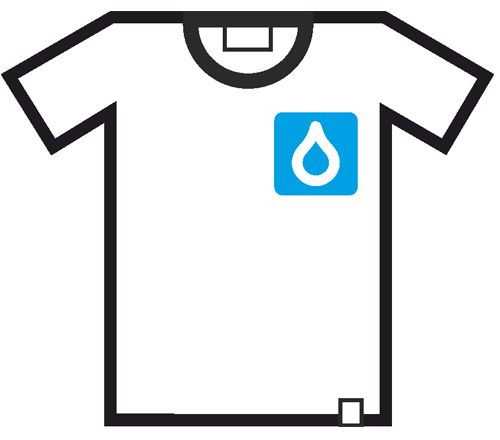

LEFT BREAST

2″ – 4.5″ wide

CENTER CHEST

7″ x 12″ wide

FULL SIZE

Approx 13″ x 18″

SLEEVE

2″ – 4.5″ wide

NAPE

2″ – 4.5″ wide

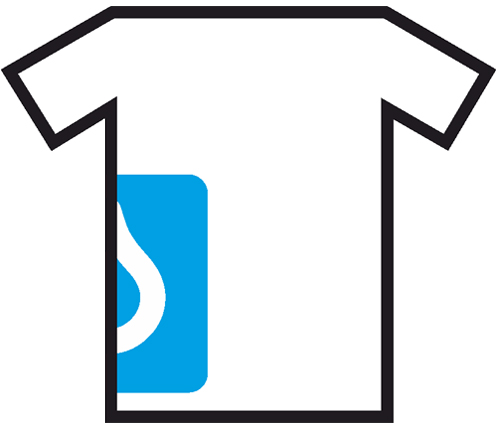

SIDE UNDERARM

10″ Height

Our inks and standard print practices are best suited to 100% cotton. So we always encourage and highy recommend choosing a high quality 100% cotton T-shirt for the best possible print finish. We can screen print on to garments with a blend of materials such as tr-blends or 100% polyester but these materials may require aditional screens at an extra cost. This is so we can print a dye block base which prevents “dye migration” which essentialy causes a discolour and dulling of the ink.